Manufacturing Operations

Rotary Klin

Automatic Weigh Batcher

An automatic weigh batcher plays a pivotal role by precisely measuring and dispensing the essential components, like aluminum powder and iron oxide, in the exact proportions required for the thermite welding process. This ensures the consistency and integrity of welds in railway tracks.

Core Making Machine

A Core Making Machine with a CO2 purging system is a vital component in thermite welding, with an impressive capacity of producing 1000 pairs of dry molds per day across 8 channels. This high-output capability ensures efficient and precise core formation, supporting the production of strong and durable thermite-welded connections in rail and metalwork applications.

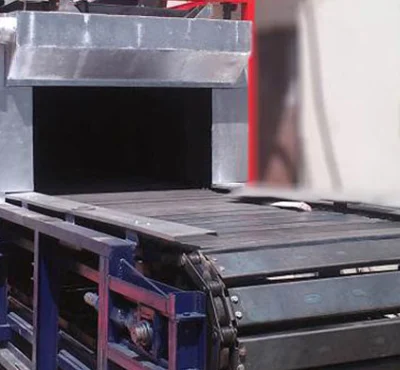

Slat Core Dryer Oven

A fully automated slat conveyorized oven is an advanced system designed for baking dry molds, Single Shot Crucible(SSC), Multi Shot Crucible with an impressive daily capacity of 1000 units. This technology offers precision and efficiency in industrial operations, making it ideal for high-volume mold baking requirements. Its conveyorized design ensures smooth and consistent production, meeting the demands of various manufacturing processes.

Physical Test

Digital Ultrasonic Machine (USFD Test)

Magnetic Crack Detection Test

Mechanical Test

Brinell Hardness Machine (3000 Kg)

The Brinell Hardness Machine (3000 Kg) is a powerful and precise testing instrument used to measure the hardness of materials. With a testing force of 3000 kilograms. This machine provides reliable data for quality assurance and material selection, helping ensure the durability and performance of components and structures.

Transverse Testing Machine (200 T Min)

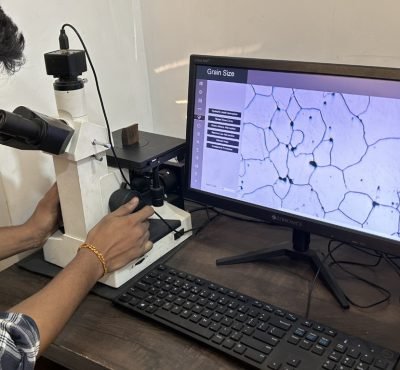

Metallurgical Test

Spectrometer

A spectrometer is used to analyze the chemical composition of various metal. By measuring the element content, it ensures the quality and consistency of welds in railway tracks and other applications, crucial for maintaining the structural integrity and safety of rail infrastructure.

Microscope Test

Chemical Test

Carbon Sulphur Determination Apparatus

Water Distillation Plant

Muffle Furnace

Hot Air Oven

Flask

Hot Plates

Chemicals

Semi Automatic Machines

VMC (Vertical Machining Center)

Thada

Thada is an essential tool in general engineering and automobile workshops, designed for swift operations. Primarily utilized for driving mandrels in and out of workpieces, it expedites production tasks efficiently. Its versatile application extends to various domains including gauge manipulation. Thada’s functionality significantly enhances productivity by streamlining processes, making it indispensable in workshop environments where speed and precision are paramount. With its robust construction and ergonomic design, it ensures durability and ease of use. Whether shaping metals or fine-tuning mechanical components, Thada stands as a reliable companion, embodying the essence of quick and effective engineering solutions.

Lathe

Lathes stand as the bedrock of machining, orchestrating the transformation of raw materials with unparalleled precision. These mechanical marvels spin and sculpt metals, woods, and plastics with finesse, guided by skilled hands and cutting-edge technology. From intricate designs to industrial-scale production, lathes exhibit remarkable versatility, shaping components to exacting specifications with seamless efficiency. Their timeless significance in manufacturing underscores their irreplaceable role in crafting everything from intricate parts to robust structures. As the cornerstone of machining, lathes epitomize craftsmanship, blending tradition with innovation to forge the foundation upon which modern industry stands.

Power Press

Power presses, integral to metalworking, employ immense force for forming and stamping operations across diverse industries. These robust machines, characterized by their heavy-duty build, play a crucial role in shaping raw materials into desired configurations with precision and efficiency. Employing hydraulic or mechanical mechanisms, power presses exert significant pressure to mold metals, producing intricate components for various applications. Their versatility and strength make them indispensable assets in manufacturing processes, ensuring the seamless production of quality goods. From automotive to aerospace sectors, power presses remain essential for achieving precise outcomes in shaping metal sheets and fulfilling the demands of modern industrial production.

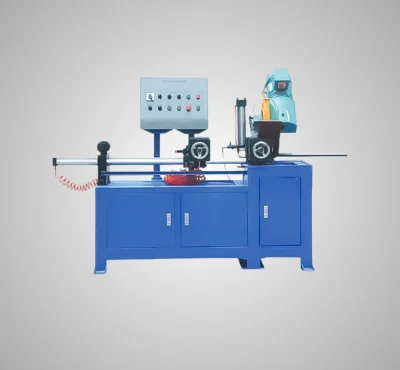

Cutter

Cutters are indispensable tools for precise material removal, serving as vital components in both manufacturing and construction industries. These tools enable artisans and professionals to shape materials with accuracy and efficiency, ensuring intricate designs and precise measurements are achieved. In manufacturing, cutters are utilized across various sectors, from automotive to aerospace, for shaping metals, plastics, and composites. In construction, they facilitate the cutting of materials like wood, concrete, and tiles, enabling the creation of structures with precision and finesse. Whether it’s crafting intricate components or shaping large-scale constructions, cutters are instrumental in achieving quality and precision in diverse applications.

Chopper Machine

Chopper machines revolutionize food preparation in commercial kitchens by efficiently cutting and dicing ingredients with precision. These versatile appliances streamline culinary tasks, saving time and effort for chefs and kitchen staff. With various blade options, they can handle a wide range of foods, from vegetables to meats, consistently producing uniform cuts. This consistency enhances presentation and cooking evenness, ensuring quality dishes for customers. Chopper machines not only expedite prep work but also contribute to operational efficiency, allowing kitchens to meet high demand with ease. Overall, they are indispensable tools in modern culinary environments, optimizing workflow and enhancing culinary output.

Electrical Furnace

Electrical furnaces are pivotal in industrial operations, utilizing electricity to produce intense heat crucial for processes such as metal smelting and heat treatment. These furnaces employ resistive heating elements to convert electrical energy into thermal energy, achieving temperatures suitable for melting and refining metals or annealing materials. Their precision and efficiency make them indispensable in various sectors, including metallurgy, manufacturing, and research. By controlling voltage and current, they ensure consistent temperatures, enhancing product quality and process reliability. With advancements in technology, modern electrical furnaces offer improved energy efficiency and environmental sustainability, aligning with evolving industrial demands and regulations.

Electroplating Tank

Electroplating tanks are essential apparatuses in electroplating processes, enabling the deposition of thin metal coatings onto diverse materials. These tanks serve as controlled environments where metal ions in solution are attracted to the substrate, forming a uniform and adherent coating. With adjustable parameters like temperature, current density, and composition of electrolyte solutions, these tanks ensure precise coating thickness and quality. Widely employed across industries including automotive, electronics, and jewelry, electroplating tanks play a pivotal role in enhancing corrosion resistance, improving conductivity, and augmenting aesthetics of finished products. Their versatility and efficiency make them indispensable tools in modern manufacturing processes.

Surface Grinder

Sander machines

Sander machines are indispensable tools in woodworking and manufacturing, adept at smoothing and refining surfaces to perfection. Utilizing various abrasive techniques, they eliminate imperfections and impart a flawless finish, enhancing both aesthetic appeal and functionality. Whether shaping raw lumber or refining intricate details, these machines ensure precision and consistency, vital for achieving desired results in diverse applications. Their versatility makes them indispensable in crafting furniture, cabinetry, and other wooden products, as well as in manufacturing industries where smooth surfaces are paramount. From hobbyists to professionals, sander machines streamline the production process, elevating the quality of finished products with efficiency and finesse.

Buff machines

Buffing machines are essential tools in metalworking and beyond, adeptly refining surfaces to a radiant sheen. These machines meticulously polish various materials, from metals to plastics, culminating in a high-gloss finish that enhances their aesthetic appeal and functional durability. Employed across industries, buff machines meticulously smooth out imperfections, achieving impeccable surface quality and mirror-like reflections. Their precision and efficiency make them indispensable in automotive, jewelry, and manufacturing sectors, where impeccable finishes are paramount. With their ability to transform raw materials into polished masterpieces, buffing machines stand as stalwarts of craftsmanship and excellence in surface refinement.

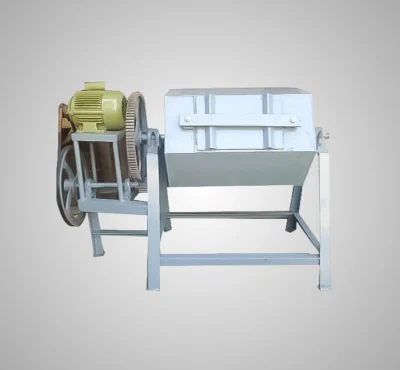

Sieving machines

Sieving machines are vital tools in industries requiring precise particle classification. Employing meshed screens or sieves, they efficiently separate particles based on size, ensuring uniformity in products like powders, grains, or aggregates. These machines operate on the principle of passing materials through meshes, allowing smaller particles to fall through while larger ones are retained. Widely used in food processing, pharmaceuticals, and mining, sieving machines streamline production by eliminating oversized or undersized particles, enhancing product quality and consistency. From quality control to material refinement, they play a pivotal role in optimizing processes, ensuring adherence to stringent size specifications with speed and accuracy.

Bench grinders

Bench grinders are indispensable stationary tools, vital for honing, grinding, and molding cutting tools and metal items. Featuring abrasive wheels, they efficiently sharpen blades, remove excess material, and shape metal to precision. Commonly employed in workshops and garages, bench grinders offer versatility for various tasks, from smoothing welds to crafting intricate designs. With adjustable speeds and wheel sizes, they cater to diverse grinding needs, ensuring optimal results. Safety measures like adjustable tool rests and eye shields enhance user protection. Bench grinders are essential for metalworking enthusiasts, craftsmen, and professionals seeking precision and efficiency in their projects.

Polish machines

Dryers

Dryers play a pivotal role in industrial drying processes by efficiently extracting moisture from various materials. Employed across diverse sectors, from food processing to manufacturing, they ensure optimal product quality and shelf life. Utilizing heat, airflow, or specialized techniques like desiccation, dryers expedite moisture removal, enhancing efficiency and reducing production time. Their versatility accommodates a wide range of materials, including grains, textiles, and chemicals. With precise control mechanisms and advanced technologies, modern dryers minimize energy consumption while maximizing output, making them indispensable in industrial operations worldwide.