Exothermic Welding Manufacturer & Supplier [country]

We manufacture exothermic welding powder and exothermic weld graphite molds. We also supply and provide exothermic welding services across [country].

AmiableWeld® is the leading manufacturer and supplier of exothermic welding products [country].

Exothermic welding is known in the market by various brand names such as AMIABLEWELD, CADWELD, ERICO, EXOWELD, KUMWELL, FURSEWELD, THERMOWELD, and AIWELD. At AmiableWeld®, we are one of the largest manufacturers of exothermic weld powder and exothermic welding graphite molds [country] and overseas.

Understanding Exothermic Welding

Exothermic welding is a specialized technique used to create robust electrical connections through a unique chemical reaction. This process involves igniting a specially formulated mixture that generates intense heat. This high temperature is sufficient to melt and fuse metal components, resulting in a seamless and enduring bond. This method is highly valued for its reliability and strength, making it essential in various critical applications.

In the solar industry, exothermic welding is instrumental in connecting the components of solar panels to ensure optimal performance and efficiency. Similarly, in electrical substations, this technique is used to create strong and dependable connections between various electrical parts, ensuring safe and effective power distribution. Additionally, exothermic welding is vital in earthing systems, where it helps establish secure ground connections to prevent electrical faults. It also plays a crucial role in lightning protection systems, where it ensures reliable connections that can withstand the immense energy of lightning strikes. This process ensures that connections are not only durable but also able to withstand harsh environmental conditions and high electrical currents.

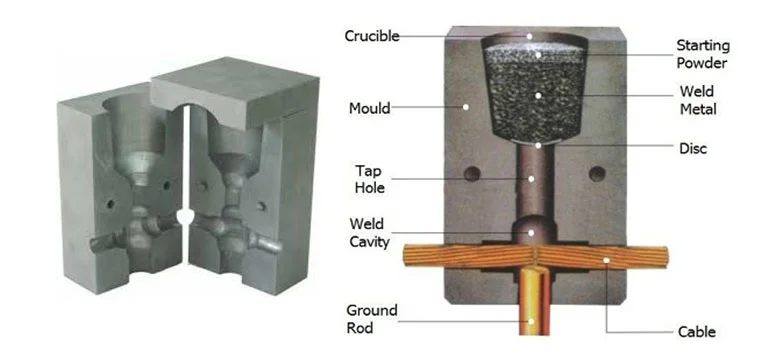

Exothermic Welding Process

Exothermic Welding Animated Demo

Exothermic Welding Live Demo

The Exothermic Welding Process Explained Step-by-Step

Exothermic welding is a specialized technique widely used for creating permanent connections between copper conductors. Here’s a step-by-step breakdown of how this process works, especially when carried out by a leading exothermic welding manufacturer [country] like Amiable Impex.

Preparation: The first step involves preparing the metal surfaces that need to be joined. For optimal results, the copper conductors are cleaned thoroughly to remove any dirt or oxidation. This ensures a clean and effective bond.

Setup: Next, a specially formulated exothermic welding mixture is prepared. This mixture, often containing metal oxides and other materials, is placed in a pre-designed mold that fits around the copper conductors.

Ignition: The mixture is then ignited using a starter powder. This reaction produces extremely high temperatures—often exceeding 2,000 degrees Celsius. These temperatures are enough to melt the copper and create a molten pool around the joint area.

Fusion: As the molten metal cools, it solidifies and forms a strong, permanent bond between the copper conductors. The result is a highly durable and reliable connection that can handle substantial electrical currents without degradation.

Inspection: Once the welding is complete, the connection is inspected to ensure it meets quality standards. At Amiable Impex, we guarantee that our products undergo rigorous testing and are certified by CPRI, CE, and ROHS. We also hold ISO 9001:2008 certification, reflecting our commitment to high-quality standards.

Amiable Impex, a leading exothermic welding manufacturer [country], prides itself on delivering high-quality products with quick lead times and fast response rates. Our commitment to customer satisfaction and adherence to stringent testing and certification processes ensures that our exothermic welding solutions are both reliable and effective.

Exothermic Welding vs. Arc Welding: Quality and Cost Comparison

| Exothermic Welding | Arc Welding |

|---|---|

| Durability: Creates a strong, permanent bond through a chemical reaction. Ideal for critical applications like electrical connections in solar panels, substations, and earthing systems. Products from an exothermic welding manufacturer in India like Amiable Impex are known for their durability. | Strength: Produces strong welds, but the strength can vary based on the welder's skill and control over the process. Suitable for various materials and thicknesses. |

| Consistency: Provides uniform quality due to the automated chemical reaction, ensuring consistent bonding in critical applications. | Consistency: Quality can be less consistent due to manual control over heat and filler material. Variations in technique can affect the final weld's strength. |

| Cost: Higher initial setup cost but lower operational costs and minimal maintenance. Long-term value is enhanced by durability. | Cost: Lower initial cost but higher operational costs due to energy, electrodes, and shielding gases. Maintenance and repairs can add to expenses. |

| Testing and Standards: Products are rigorously tested and certified (CPRI, CE, ROHS). An exothermic welding manufacturer in India like Amiable Impex ensures adherence to high standards. | Testing and Standards: Meets high standards, but quality control depends on the welder's expertise and equipment used. |

| Applications: Ideal for solar energy, electrical substations, earthing, and lightning protection systems where reliability is crucial. | Applications: Versatile and used across various industries, but may require more frequent repairs and maintenance in demanding applications. |

Discover the Power of Exothermic Welding in [country] with AMIABLEWELD

Are you in need of a reliable, permanent solution for joining copper conductors or copper tapes/strips? Look no further than exothermic welding, the gold standard for bonding copper to copper cable. Our lightning protection and grounding systems ensure connections that surpass the current-carrying capacity of the conductors they join, providing unparalleled safety and efficiency.

At AMIABLEWELD, we deliver superior connections with higher fusing capacities than the conductors themselves. But our expertise doesn’t stop at copper. We also excel in joining stainless steel, cast iron, steel, brass, bronze, and other similar metals. Whether you need to bond similar or dissimilar metals, exothermic welding is your best option.

Our comprehensive services include the manufacture of high-quality exothermic welding powder and durable graphite molds. We proudly serve all of [country].

Trust AMIABLEWELD to meet your exothermic welding needs and provide the assurance you deserve. Contact us today to learn more about our products and services!

Exothermic Welding Process

Exothermic welding is a welding process that utilizes an exothermic reaction, a chemical process that releases energy in the form of extremely high temperatures and light. This process is used to permanently join metal connections, ensuring durable and reliable electrical connections. Discover the power of exothermic welding

Exothermic Welding Kit

Exothermic welding requires graphite molds, handle clamps, steel disks, weld powder, and ignite powder. Safety gloves and flint guns ensure safe and reliable operation. Brushes and slag removal tools clean surfaces, while sealing compounds prevent leaks. A flame torch preheats materials for optimal

results.

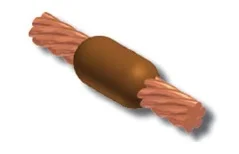

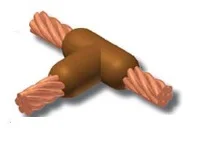

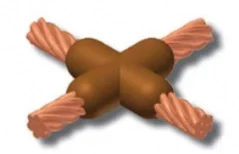

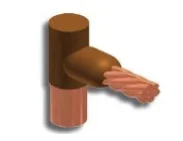

Exothermic Weld Common Joints

Exothermic welding, pioneered by Amiable - AURAWELD®, creates strong, permanent connections. Common joints include cable to cable for electrical continuity, cable to ground rod for grounding, and cable to rebar for reinforced concrete. Other key joints are cable to steel surface, ground rod to ground rod, and cable to busbar for electrical panels.

Cable To Cable Joints - Exothermic Weld

Cable to Rod Joints - Exothermic Weld

Cable To Bar Joints - Exothermic Weld

Cable To Surface (Steel/Copper) Joints - Exothermic Weld

Bar to Bar Connections (BB)- Exothermic Welding

Bar To Ground Rod Connections (BR)- Exothermic Welding

Exothermic Welding Accessories

Exothermic Weld Camp Handler

Exothermic Welding Flit Gun

Exothermic Welding Safety Gloves

Exothermic Welding Powder

Exothermic Welding Slug Removal Tool

Exothermic Welding File Brush

Exothermic Welding Steel Disk

Exothermic Welding Flame

Exothermic Weld Graphite Mould

Contact us or Drop an email | We’re here to help!

Contact us : +91-9594899995 or Drop an email to info@amiableimpex.com | We’re here to help!

Amiable Impex isn’t just a manufacturer; it’s the brainchild of Mr. Maulik Shah, a visionary leader with over a decade of experience in the exothermic welding manufacturing industry. Founded with the ambition to lead both India and the world in exothermic welding manufacturing..

Head Office

501-A, Surya Darshan Building, Pai Nagar, J. S. Road, Borivali West,

Mumbai – 400092, India

Copyright © 2024 Amiable Impex. Designed by Pixela