Exothermic Weld and Weld Powder by Amiable Impex: The Leading Exothermic Welding Manufacturer and Biggest Exothermic Welding Powder Manufacturer

Born from a Vision. Driven by Innovation.

Amiable Impex isn’t just a manufacturer; it’s the brainchild of Mr. Maulik Shah, a visionary leader with over a decade of experience in the electrical metal industry. Founded with the ambition to lead both India and the world in exothermic welding manufacturing, Amiable Impex has charted a path of continuous growth and innovation.

Under Mr. Shah’s leadership, Amiable Impex has set new standards in exothermic welding manufacturing, blending expertise with innovation to shape the future of the industry.

Beyond Performance, Redefining Reliability:

At Amiable Impex, as a leading exothermic welding manufacturer, we transcend mere functionality. Our products, born from relentless R&D and crafted with meticulous precision, not only excel in electrical and mechanical performance but set the benchmark for enduring reliability. We don’t follow the pack; we set the trends, proactively responding to diverse customer needs with superior value-added solutions.

We are Leading Exothermic Welding Powder Manufacturer and Innovator in Graphite Mould and Weld Metal Solutions

We aren’t just a manufacturer; it’s the brainchild of Mr. Maulik Shah, a visionary leader with over a decade of experience in the electrical metal industry. Founded with the ambition to lead both India and the world in exothermic welding manufacturing, we have charted a path of continuous growth and innovation.

Under Mr. Shah’s leadership, We have set new standards in exothermic welding manufacturing, blending expertise with innovation to shape the future of the industry.

We are Setting New Standards in Quality and Innovation for Exothermic Weld Solutions

At Amiable Impex, we are pioneers in the exothermic weld and welding process, offering top-quality weld powder and exothermic weld powder that ensures superior performance for a wide range of applications. Our exothermic welding process guarantees robust, durable connections, especially in challenging environments such as railway systems and electrical connections.

Our weld solutions are designed to work seamlessly with copper, ensuring copper-bonded connections that provide exceptional strength and reliability. With our graphite mold technology, we achieve precise and efficient welds that withstand high-temperature conditions, offering unparalleled metal bonding and electrical connections.

We prioritize the exothermic reaction, which facilitates rapid molten metal flow, ensuring that your copper oxide is completely transformed into a secure, lasting connection. Whether for grounding or other critical applications, Amiable Impex delivers the reliability you need for earth systems and conductors, utilizing the best weld materials and exothermic weld powder in the market.

Exothermic Welding Process

The Efficient Method for Reliable Metal Connections

Exothermic Welding Animated Demo

Exothermic Welding Live Demo

The exothermic welding process is an efficient and reliable method for creating strong, long-lasting joint metal connections. This process, also known as exothermic bonding, offers several advantages, making it one of the most preferred techniques for joining metals, especially in industries requiring high-quality electrical connections and grounding solutions.

What is Exothermic Welding?

Exothermic welding is a process extensively used by an Exothermic Welding Manufacturer to create molecular joints between alloys, such as copper to copper or copper to steel, through a chemical reaction that generates fused metal. This process relies on a special exothermic weld powder, which is a mixture of powdered copper oxide and aluminum. When ignited, the powder reacts to produce an intense, high-temperature reaction that melts the alloy and ensures effective bonding.

One of the key advantages of exothermic welding, widely recognized by every Exothermic Welding Manufacturer, is that it requires no auxiliary power or heat source, making it a self-sustaining process. The reaction between the powdered copper oxide and aluminum generates sufficient energy to activate the weld, allowing it to flow into the weld cavity, fill available spaces, and form a durable connection.

Advantages of Using Exothermic Welding

There are many advantages of using exothermic welding, especially when offered by a trusted Exothermic Welding Manufacturer, for critical applications such as electrical grounding and high-quality electrical connections. Some of the key benefits include:

- No Auxiliary Power Required: The exothermic welding system, provided by any reputable Exothermic Welding Manufacturer, is completely independent of auxiliary power or heat, relying solely on the chemical reaction to generate the required heat. This makes it ideal for remote locations where electricity may not be readily available.

- Strong and Durable Connections: Exothermic welded connections are known for their high integrity and ability to withstand high currents and temperature reactions. The molecular bond ensures the connection is as strong as the parent alloy, a hallmark of quality from an experienced Exothermic Welding Manufacturer.

- High-Temperature Resistance: The high-temperature reaction of powdered copper oxide creates a connection that is resistant to extreme temperatures. This makes it perfect for applications in Railtrack systems, metal industry environments, and electrical substation work.

- Efficient and Safe: The process is quick and safe, as it takes place without the need for external power or heat. Once activated, the exothermic reaction creates an intense but controlled heat that melts the element and forms the weld, reducing the risk of accidents.

- Long Lifespan: Exothermic welded connections are highly resistant to corrosion, ensuring longevity and extended lifetime of the installation. The durability of these connections underscores the reliability of a professional Exothermic Welding Manufacturer.

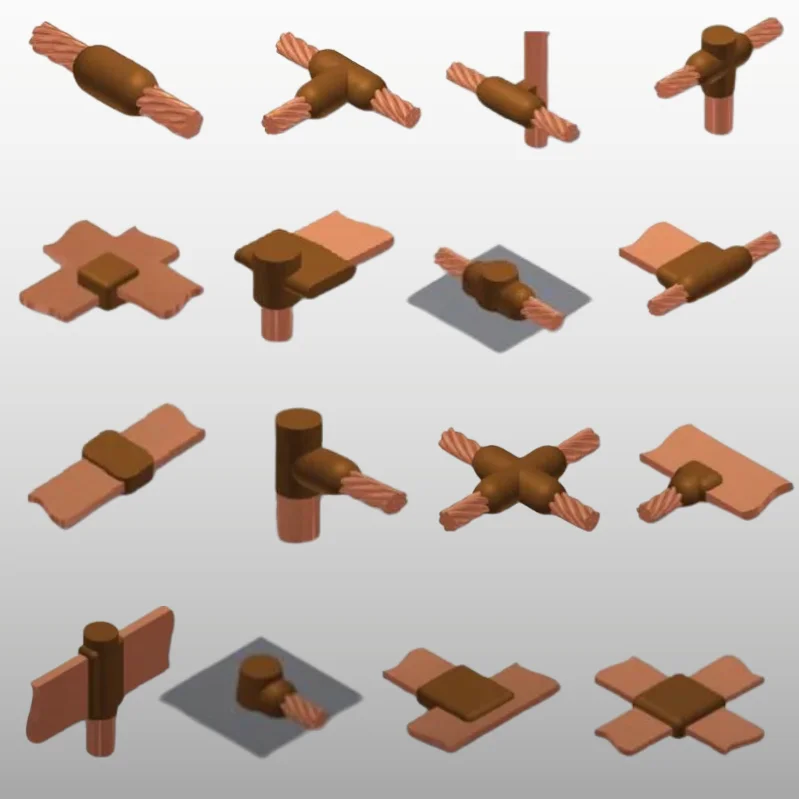

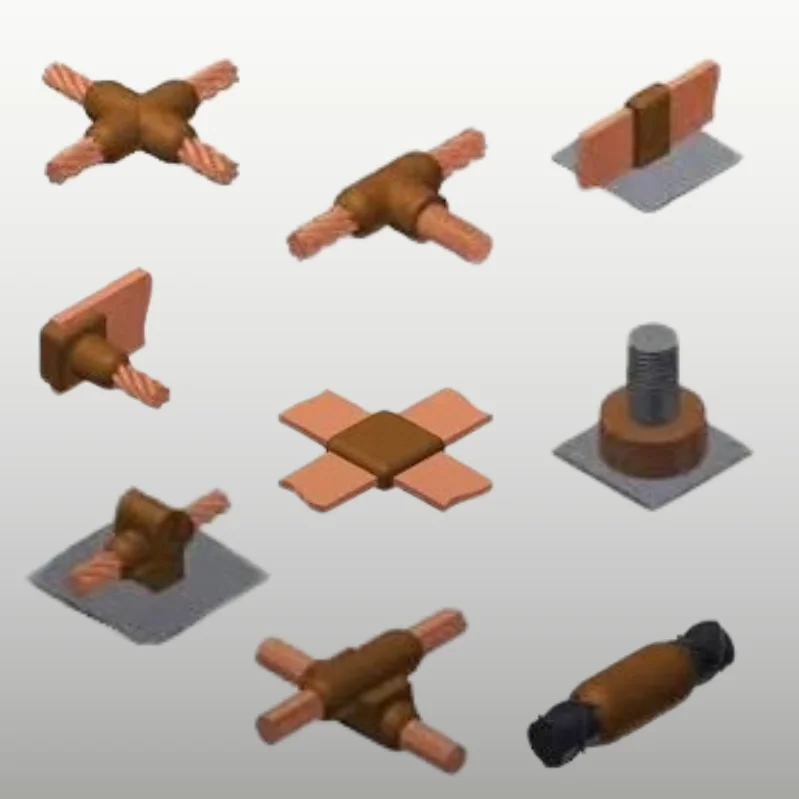

Crafting Quality: Explore Our Diverse Exothermic Welding Manufacturing Portfolio

The Exothermic Welding Process by an Exothermic Welding Manufacturer

The process of exothermic welding, widely utilized by an Exothermic Welding Manufacturer, involves several steps to ensure a perfect connection:

The surfaces of the alloy to be welded (such as copper or copper alloy) are cleaned to ensure optimal bonding. This involves removing any oxidation or debris that could interfere with the welding procedure.

A graphite mold shapes the fused metal during the welding procedure. Graphite molds, often provided by a trusted Exothermic Welding Manufacturer, are designed to withstand the intense heat generated during the reaction.

The exothermic weld powder is placed into the mold. This powder, containing a mix of powdered copper oxide and aluminum, reacts to produce the heat required for the welding procedure.

A starting reactant, usually a small ignition source, initiates the exothermic reaction. This reaction provides enough energy to activate the weld.

The molten metal flows into the mold, filling the cavity and joining the metals together. The process creates a molecular bond that is as strong as the base metals themselves, a testament to the precision of an experienced Exothermic Welding Manufacturer.

Once the weld has formed, it is allowed to cool and solidify. The result is a permanent, durable connection capable of withstanding harsh conditions.

Semi-Permanent Graphite Mold for Exothermic Welding by an Exothermic Welding Manufacturer

The semi-permanent graphite mold plays a crucial role in the exothermic welding process, a key offering by any reputable Exothermic Welding Manufacturer. Made within a semi-permanent graphite structure, it is designed to withstand the intense temperatures generated during the welding reaction. This mold ensures the accurate containment of the exothermic weld powder, enabling a controlled environment for the high-temperature reaction.

Graphite molds provided by an Exothermic Welding Manufacturer offer precise molding, which is essential for creating strong, durable bonds between metals such as copper to copper and copper to steel. Additionally, the semi-permanent graphite mold, capable of handling high temperatures, is built for durability and can be reused multiple times, ensuring efficiency and reliability for various welding applications. The powder and its accessories used in the process are also critical in maintaining the quality and consistency of the weld.

Why Choose Amiable Impex as Your Exothermic Welding Manufacturer?

As a trusted Exothermic Welding Manufacturer, Amiable Impex provides top-tier welding powder and accessories to ensure that the exothermic welding system delivers superior results. We are the biggest exothermic welding powder manufacturer, and our products are renowned for their quality and reliability. Here are some reasons to choose Amiable Impex for your exothermic welding needs:

- Expertise and Innovation: With over a decade of experience in the metal industry in both India and internationally, we have refined the exothermic welding procedure to provide optimal results.

- Wide Range of Applications: Our products are ideal for various industries, including electrical grounding, track systems, and metal fabrication.

- Quality Assurance: Our exothermic welding powder and graphite mold are manufactured to the highest standards, ensuring the strength, durability, and reliability of your welded connections.

- Custom Solutions: As a leading Exothermic Welding Manufacturer, we offer a range of welding accessories and kits, including the exothermic welding kit, to meet the specific needs of our customers.

Crafting Quality: Explore Our Diverse Exothermic Welding Manufacturing Portfolio

Our Facilities – Manufacturing Operations

As a trusted Exothermic Welding Manufacturer, we pride ourselves on advanced facilities and precision-driven manufacturing operations.

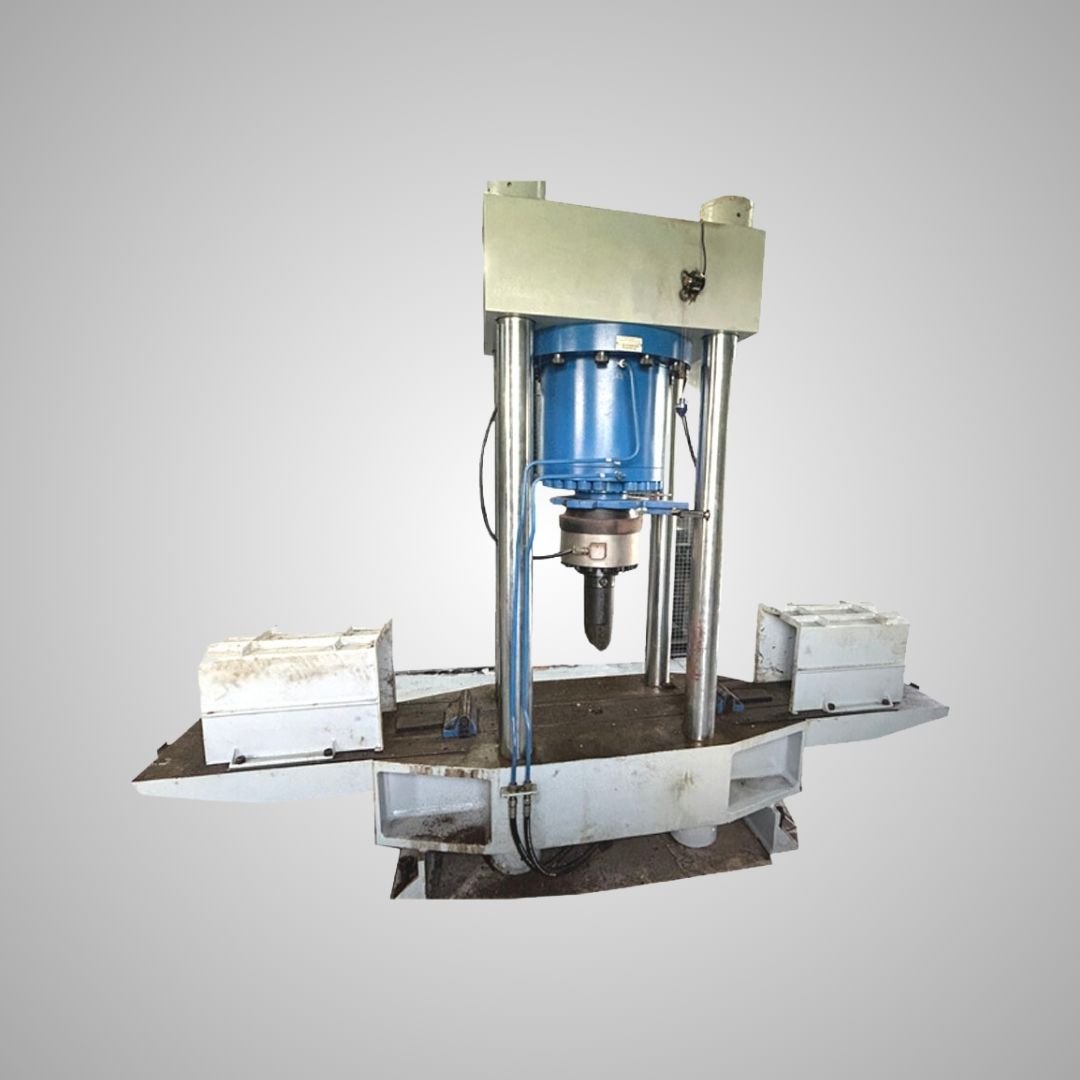

Rotary Kiln

A rotary kiln, often utilized in thermite welding, is a specialized cylindrical furnace capable of reaching high temperatures. This equipment plays a crucial role in heating and fusing metals, enabling a strong and durable bond between two pieces. Its controlled rotation ensures uniform heating, making it an indispensable tool for thermite welding applications.Automatic Weigh Batcher

The automatic weigh batcher is essential for precision in the thermite welding process. It accurately measures and dispenses key components, such as aluminum powder and iron oxide, in the exact proportions required. This precision ensures consistency and the structural integrity of welds, especially in railway tracks, a key focus area for any leading Exothermic Welding Manufacturer.

Physical Test

Ultrasonic Flaw Detection is a valuable technique in thermite welding processes, ensuring the quality and integrity of rail and metal connections. Employing high-frequency sound waves to detect flaws or irregularities within the weld, plays a crucial role in maintaining the safety and durability of thermite-welded joints. This method is essential for meeting stringent quality standards in rail and metalwork applications.

Mechanical Test

The Brinell Hardness Machine (3000 Kg) is a powerful and precise testing instrument used to measure the hardness of materials. With a testing force of 3000 kilograms, this machine provides reliable data for quality assurance and material selection, helping ensure the durability and performance of components and structures. The hardness test provides accurate measurements of the material’s weld metal characteristics, essential for determining its ability to withstand high temperature and hot metal environments.

Transverse Testing Machine (200 T Min)

The Transverse Testing Machine, with a minimum capacity of 200 tons, is a critical tool used for inspecting the strength and stability of rail tracks after thermite welding. This testing ensures that the welded joints can withstand heavy loads and transverse forces, contributing to the safety and reliability of rail infrastructure. It plays a vital role in quality control and compliance with industry standards in rail track maintenance and construction. The machine also helps ensure that exothermic welded connections can handle the stresses experienced during regular use, meeting the required performance standards for metal used in rail systems.

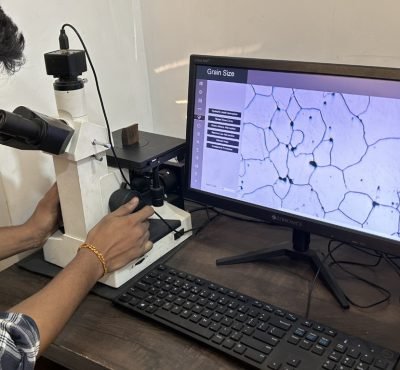

Metallurgical Test

A spectrometer is used to analyze the chemical composition of various metals. Measuring the element content ensures the quality and consistency of welds in rail tracks and other applications, crucial for maintaining the structural integrity and safety of rail infrastructure. This tool is essential for identifying the composition of the joint metal and ensuring that the exothermic weld has the necessary properties to withstand high-stress conditions, contributing to long-lasting and reliable electrical connections.

The microscope test is an essential quality control procedure. During this process, a sample from the welded joint is meticulously examined under a microscope to assess its microstructure. This examination provides critical insights into the integrity of the weld, including factors like grain size, grain boundaries, and any potential defects. It plays a key role in confirming that the exothermic weld meets the required standards for strength, durability, and consistency in welded connections, ensuring the safety of rail infrastructure.

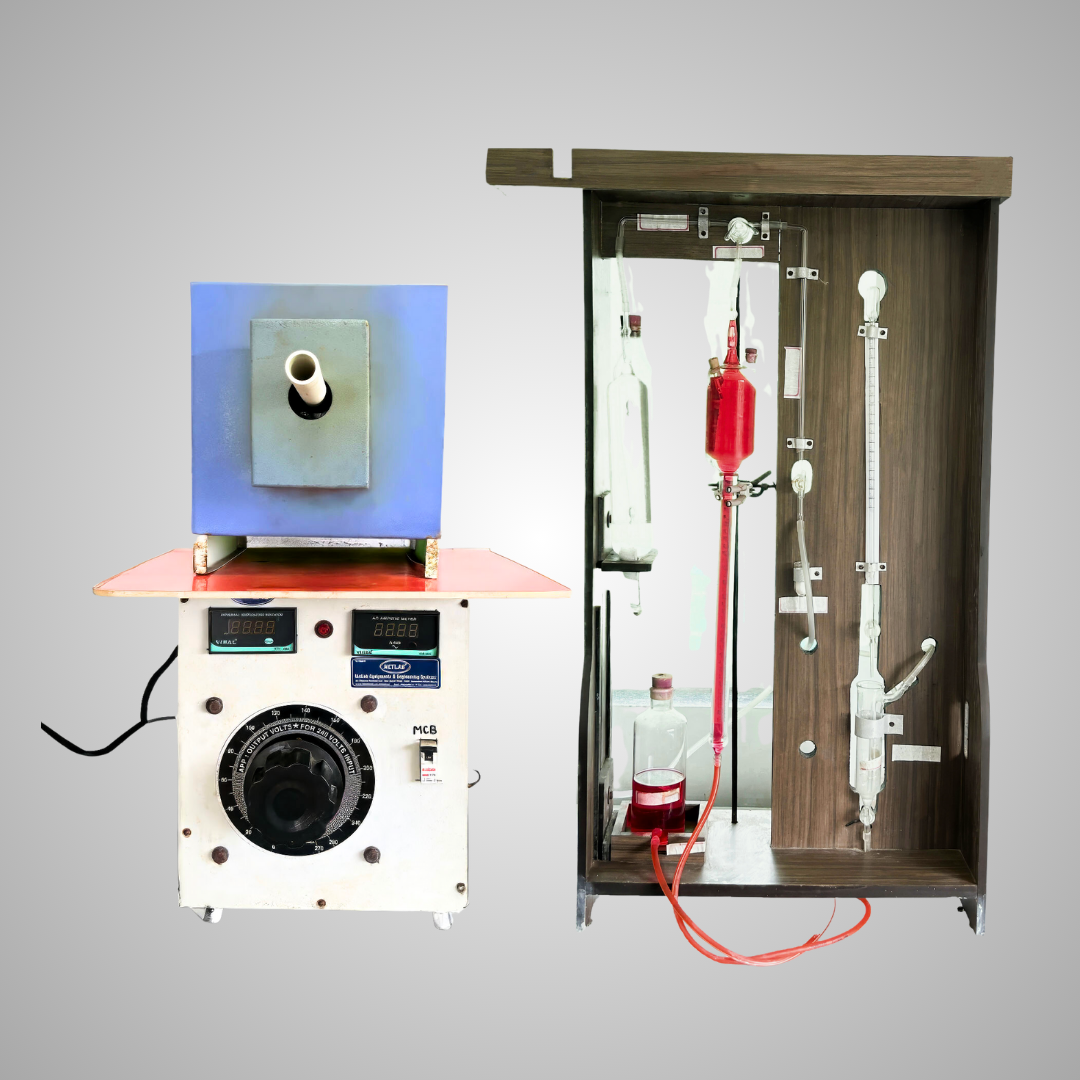

Chemical Test

A Carbon Sulphur Determination Apparatus is a vital tool in laboratories for accurately measuring the carbon and sulfur content in various substances. This device utilizes high-temperature combustion to analyze the elemental composition, enabling researchers to assess the purity and quality of materials, making it indispensable for quality control and analytical chemistry in scientific settings. The high-temperature reaction involved helps determine the integrity of metal samples, ensuring they meet the necessary standards for welding applications.

A Water Distillation Plant is a crucial component in laboratory settings, providing high-purity water for experiments and analyses. It employs distillation techniques to remove impurities, ensuring that the water used in scientific research is of the highest quality and free from contaminants. This water is vital for producing high-quality welds and ensuring that the exothermic weld powder used in industrial applications is free of contaminants that could impact performance.

A Muffle Furnace, a common fixture in laboratories, is a high-temperature heating device used for processes such as ashing, burning, and heat treating. It ensures controlled and precise heating, making it invaluable for various scientific and analytical applications. The furnace’s ability to achieve high-temperature conditions is essential for testing materials like graphite molds and weld powder, ensuring their performance in exothermic welding processes.

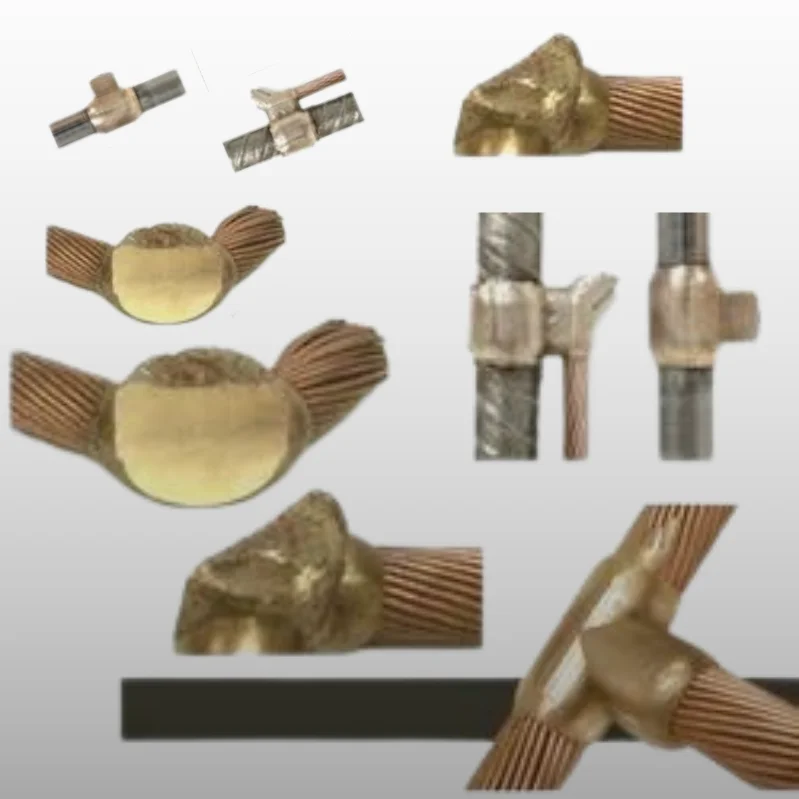

What and Which Metal can be Welded through Exothermic Weld Powder?

Exothermic welding powder is a powerful solution for joining various metals, making welding possible for copper to copper, copper to steel, and other metal types. The process ensures a strong, permanent bond through a chemical reaction that produces heat, which is used to melt the fused metal. Metals like copper, steel, and aluminum can be welded efficiently using exothermic welding powder, providing a reliable connection that is resistant to corrosion and high temperatures. The process uses a high-temperature reaction to melt the metals. Semi-permanent graphite molds are often used to contain the molten weld powder during the welding process.

What is Exothermic Weld?

Exothermic welding, also known as exothermic bonding, is a welding technique that uses exothermic weld powder to create a high-temperature reaction. This reaction produces the heat necessary to melt the joint metal, allowing for a seamless bond between metals like copper and steel. The process requires no external power or heat source, making it a self-contained and highly efficient method for producing durable and high-quality welded connections. The exothermic welding procedure is commonly used in industries such as rail, electrical connections, and grounding systems, ensuring a reliable and strong connection that is resistant to corrosion and high temperatures.

What is the Process for Exothermic Weld or How is the Metal Welded by an Exothermic Welding Manufacturer?

The exothermic welding procedure begins with placing the exothermic weld powder into a graphite mold, which is then ignited to trigger a chemical reaction between the powder components. This reaction generates intense heat, melting the weld metal and bonding the metals together.

The process occurs quickly and safely, forming a molecular joint between metals like copper to copper or copper to steel. The molten weld metal flows into the cavity, filling any available space and creating a strong, durable bond that can withstand high temperatures and resist electrical resistance. As a leading exothermic welding manufacturer, we ensure that the entire process results in a reliable, high-quality welded connection.

Excellence in Every Detail: Our Uncompromising Commitment to Quality

Exploring Our Precision Testing Tools