Essential Tools for the Exothermic Welding Process Using an Exothermic Welding Kit

As a leading manufacturer, supplier, and exporter of Exothermic Welding Kit and Moulds, we proudly serve customers across the globe. Our comprehensive range of exothermic welding solutions is designed to meet the highest industry standards, ensuring reliable and efficient electrical connections.

Each Exothermic Welding Kit and Mould is crafted with precision and quality, guaranteeing superior performance in various applications, from grounding systems to lightning protection.

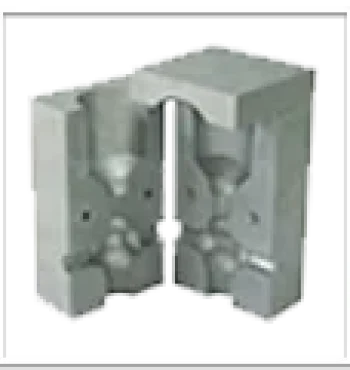

Graphite Mould for Exothermic Weld

Graphite molds play a crucial role in any Exothermic Welding Kit, offering a durable, heat-resistant container that shapes the molten metal flawlessly. They guarantee precise and consistent welds, catering to different conductor configurations and sizes. Renowned for their longevity and exceptional thermal conductivity, these molds are indispensable for achieving top-quality results.

Mould Handle Clamp (Universal)

The universal mold handle clamp, an essential component of the Exothermic Welding Kit, ensures secure and effortless handling of graphite molds during welding. It delivers a firm grip for stability and safety, enabling quick and easy mold positioning and removal. This enhances the efficiency and precision of your welding operations.

Steel Metal Disk

Steel metal disks, an essential part of Exothermic Welding Accessories, are used in exothermic welding to contain the molten metal and prevent it from escaping the mold. These disks ensure a controlled and efficient reaction by providing a barrier that directs the molten metal into the desired weld joint, ensuring a clean and strong connection.

Exothermic Weld Powder

Exothermic weld powder is a crucial component of the Exothermic Welding Kit, consisting of a blend of metal oxide and aluminum powder. When ignited, it produces an intense exothermic reaction, generating the heat required to melt and fuse the conductors, resulting in a high-quality, permanent bond. The welding kit includes all necessary accessories to ensure a seamless and efficient welding process.

Ignite Powder (Starting Powder)

Ignite powder, or starting powder, is used to initiate the exothermic reaction in the weld powder. A small amount is sprinkled on top of the weld powder and ignited, triggering the reaction. It ensures a reliable and consistent start to the welding process.

Hand Gloves

Hand gloves are vital for protecting workers from the high temperatures and molten metal during the exothermic welding process. Made from heat-resistant materials, these gloves provide safety and comfort, allowing operators to handle equipment and materials confidently and safely.

Flint Gun

The flint gun is a tool used to ignite the starting powder in exothermic welding. It produces a spark that initiates the exothermic reaction. Flint guns are designed for ease of use and reliability, ensuring a safe and efficient ignition process.

Brush (Soft and Hard)

Brushes, both soft and hard, are used for cleaning the conductors and molds before welding. Soft brushes remove fine particles, while hard brushes tackle more stubborn contaminants. Proper cleaning ensures better weld quality and adherence by eliminating any impurities that could affect the bond.

Slag Removal Tool

The slag removal tool is used to clean off the slag, or residue, left on the weld joint after the exothermic reaction. This tool ensures a clean and smooth surface on the finished weld, which is crucial for both aesthetic and functional purposes, enhancing the overall quality of the weld.

File Card

A file card is used to clean and maintain the brushes used in the welding process. It removes debris and buildup from the bristles, ensuring that the brushes remain effective for cleaning the conductors and molds, thereby maintaining the quality of the welding process.

Sealing Compound

The sealing compound is used to secure the joints and prevent leakage of the molten metal during the exothermic welding process. It ensures that the weld is contained within the mold, resulting in a precise and controlled weld. This compound is crucial for achieving high-quality, defect-free welds.

Flame Torch

A flame torch is often used to preheat the molds and conductors, removing any moisture that could affect the welding process. Preheating ensures better weld quality by promoting proper metal fusion and reducing the risk of defects caused by moisture or temperature inconsistencies.

Product Features of Exothermic Welding Kit:

Safe Operation

Easy to learn and operate without needing professional technical knowledge or special protection.

High Efficiency

Requires no external energy and uses simple tools and equipment.

Durable Connectors

Made of high-purity copper with strong corrosion resistance, forming metal bonds that do not loosen.

Superior Conductivity

The current carrying capacity of the connectors is greater than that of wire connectors.

Versatile Application

Suitable for welding copper to copper, copper to steel, and copper to galvanized steel, as well as other metal materials.

Impact Resistance

Connectors can withstand multiple large inrush current impacts without degradation.

Download Brochure!

Amiable Impex offers top-quality exothermic welding kit price at competitive rates, with delivery guaranteed within 10 to 15 days across India. Our products are tested and approved by CPRI, CE, and ROHS certified, and we are ISO 9001:2008 certified and Crisil verified, ensuring full customer satisfaction.

Amiable Impex: Your Trusted Supplier of High-Quality Exothermic Welding Kits

When it comes to reliable and high-performance exothermic welding kits, Amiable Impex stands out as a leading manufacturer, supplier, and exporter. We understand the critical need for precision and safety in welding processes, and our exothermic welding kits are designed to deliver the best results. Here’s why Amiable Impex should be your preferred supplier:

- Industry-Leading Products: We provide top-quality exothermic welding kits that are tested for durability and performance. Our kits are designed to handle a variety of welding tasks, offering excellent bonding between copper, steel, and other materials.

- Comprehensive Support: With Amiable Impex, you don’t just get a product—you get full support. From choosing the right exothermic welding kit to assisting with installation and troubleshooting, we’re here to help every step of the way.

- Durable and Efficient: Our exothermic welding kits are built for longevity, with components that ensure a high-efficiency welding process and strong, long-lasting connections.

- Certified Quality: All of our products are certified by leading industry standards, including CPRI, CE, and ROHS, ensuring that our exothermic welding kits meet safety and quality regulations.

- Quick Delivery and Competitive Pricing: We offer timely delivery across India and competitive pricing on our exothermic welding kits, so you can maintain project timelines and budgets without compromise.

Trust Amiable Impex to be your go-to source for premium exothermic welding kits that deliver exceptional results. Get in touch with us to explore our range of products and experience unparalleled quality.

Why Choose Amiable Impex for Your Exothermic Welding Kit Needs?

At Amiable Impex, we are committed to providing high-quality exothermic welding kits that meet the highest industry standards. Our products are engineered with precision and innovation, ensuring seamless welding experiences for a wide range of applications, from electrical grounding to lightning protection. Here’s why you should choose us for all your exothermic welding kit needs:

- Superior Quality: Our exothermic welding kits are manufactured using high-grade materials, ensuring durable, efficient, and safe welding connections.

- Comprehensive Range: We offer a complete range of exothermic welding accessories, including graphite molds, welding powders, and other essential components that ensure a seamless welding process.

- Reliability and Performance: Our exothermic welding kits are known for their reliable performance, providing strong, permanent bonds that will withstand extreme conditions and heavy current impacts.

- Global Reach: As a trusted exothermic welding kit supplier, we serve customers across the globe, ensuring timely delivery and exceptional customer service.

- Competitive Pricing: We offer affordable pricing without compromising on quality, making us a preferred choice for both large-scale industrial projects and specialized applications.

Choosing Amiable Impex ensures that you receive an exothermic welding solution that exceeds expectations. Contact us today to learn more about our exothermic welding kits and how we can support your welding projects worldwide.

Contact Amiable Impex for Premium Exothermic Welding Kits

Looking for top-quality exothermic welding kits? At Amiable Impex, we are your trusted partner for all welding needs, offering high-performance kits that meet the highest industry standards. Whether you are working on small-scale or large industrial projects, we provide efficient and reliable welding solutions to help you achieve optimal results.

How We Can Assist You:

- Quick Response: Our team is dedicated to providing fast and effective support. Reach out to us, and we’ll address your queries regarding exothermic welding kits promptly.

- Tailored Solutions: If you have specific requirements, we offer customized solutions to suit your unique needs, ensuring the perfect match for your welding projects.

- Efficient Service: With a focus on timely delivery and quality assurance, we ensure your exothermic welding kit reaches you without delay.

Get in Touch Today:

Contact Amiable Impex to explore our premium exothermic welding kits. Our expert team is ready to guide you through the selection process and offer any assistance you may need.